Regulator Freeze-ups

Field Topics are intended to provide useful information to the network of authorized LP-Gas and Anhydrous Ammonia distributors regarding the proper use of RegO® products. Warning Bulletins covering many of the hazards involved are available from RegO for more detailed information. These bulletins can be found in our L-500, and NH3-102 catalogs. Neither the Field Topic or the Warning Bulletins are intended to conflict with federal, state, or local ordinances and/or regulations, which should be observed at all times. This information also is not intended to be a substitute for or to supplement any training in the safe handling and use of propane and related equipment, as required by any applicable law. By providing this material, ECI assumes no responsibility for providing any such training. Only individuals properly trained in the safe handling and use of propane and related equipment should be permitted to do so, and by providing this information, ECI does not assume responsibility for providing such training.

For more information on LP Gas system requirements, refer to Liquefied Petroleum Gas Code (NFPA 58), National Fuel Gas Code (NFPA 54), National Propane Gas Association Safety Handbook, the RegO LP-Gas Serviceman’s Manual L-545, RegO catalogs L-500/NH3-102, ANSI K61.1 Safety Requirements for Storage and Handling of Anhydrous Ammonia, as well as any applicable local codes and ordinances.

Regulator Freeze-ups

Although it is rare for a RegO regulator to freeze up, it can happen when there is excessive moisture in LP gas. The freeze up occurs when moisture in the gas condenses then freezes on the cold surface of the regulator nozzle. The nozzle becomes cold when high pressure gas expands as it exits the nozzle into the regulator body.

These conditions can happen in older as well as newer LP-Gas containers when heating demands are higher during colder temperatures. Freeze-ups can also occur in pigtails that are kinked or bent where free flow of the LP-Gas is restricted. These freeze-ups can occur when the moisture, gas flow and temperature combine to create a hazardous condition. Freeze-ups can occur at temperatures above 32º F.

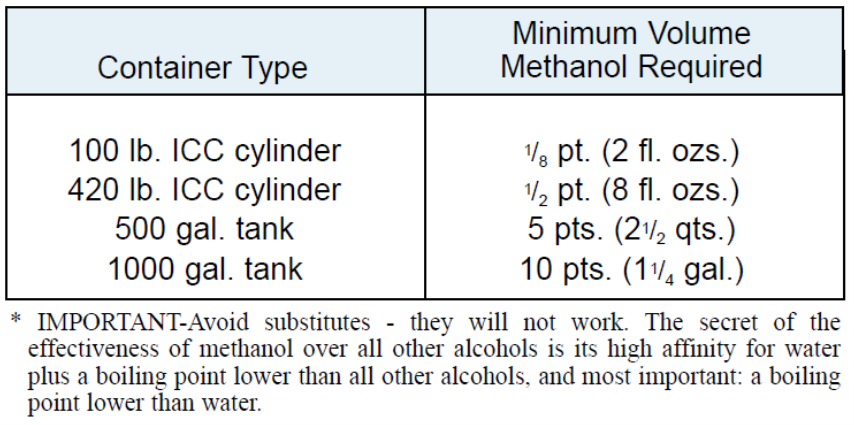

All LP-Gas should be checked for moisture content prior to delivery to consumers and proper amounts of anhydrous methanol should be added if the gas cannot be returned to the supplier. Any container suspected of having excessive moisture should be treated with the proper amount of methanol.

What to look for when you encounter a frozen or frosted regulator

- Has the container been purged properly?

A very important step which must not be overlooked by LP-Gas marketers is the importance of properly purging new LP-Gas containers. Attention to this important procedure will promote customer satisfaction and greatly reduce service calls on new installations. Refer to your RegO L-545’s serviceman’s manual on how to purge a tank properly.

- Has methanol been added to the container properly?

Whether in a new installation or existing installation LP-gas should be treated properly with Methanol to neutralize moisture. Remember when purging your tank, it is recommended to neutralize the moisture in the LP-Gas cylinder. A rule of thumb for neutralizing moisture in an ASME container calls for the introduction of at least one pint of genuine absolute anhydrous methanol* (99.85% pure) for each 100 gal. of water capacity of the container.

***Do not use methanol to remove ice from the inside of a frozen regulator. Methanol could due severe damage to the diaphragm and seat disc.***

- How is the regulator installed?

Make sure your regulator is installed higher than the container connection. This will ensure that any liquid droplets that form in the pigtail will drain back into the container. Provide a loop in your pigtail providing a trap for liquid to fall back into the container. When manifolding multiple containers, the piping must be installed to allow for any accumulation to drain back into the container.

- Replace your single stage regulators with a twin-stage or two-stage system

The chilling action is more severe in single-stage systems as gas expands from tank pressure to 11” w.c. through a single regulator nozzle. Two-stage systems can greatly reduce the possibility of freeze-ups and resulting service calls as the expansion of gas from tank pressure to 11” w.c. is divided into two steps, with less chilling effect at each regulator.

The installation of a two-stage system – one high pressure regulator at the container to compensate for varied inlet pressures, and one low pressure regulator at the building to supply a constant delivery pressure to the appliances – helps ensure maximum efficiency and trouble-free operation year-round.

- Check for restriction in your piping system

Freeze-ups can also occur when there is a restriction of flow in the inlet piping. Check to make sure your pigtails and hogtails are not kinked or bent where the free flow of the LP-Gas is restricted. If your application requires a large vapor load, then use a hogtail or pipe properly with schedule 80 piping per NFPA 58 requirements.

For additional information please refer to:

Should you have any questions or concern, please contact Cody Reeves.

Field Topic Conductor :

Cody Reeves – LPG Tech. Services Manager

10+ years as a Propane Service Technician including installation and service of gas equipment.

State of CT Licensed Gas & Oil contractor.

Graduated from a Technical high school majoring in HVAC