A better built valve,

builds a better system.

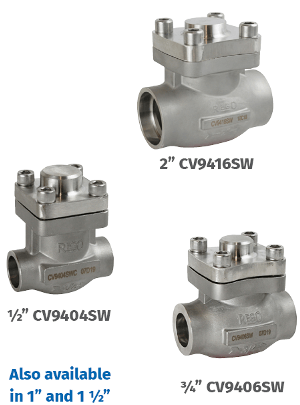

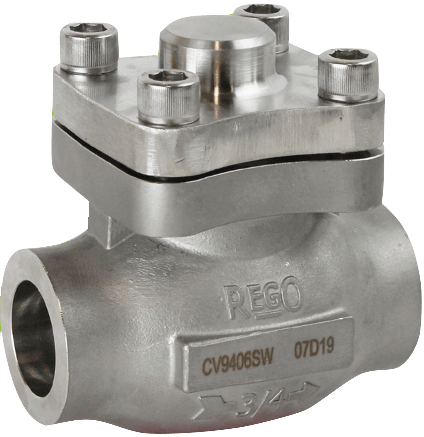

The New CV9400 Series of Stainless Steel Lift Check Valves are designed with a spring-loaded piston for installation in various piping configurations in liquid cryogenic applications, including bulk tanks, trailers and ISO tanks and for use with various cryogenic medias. This series builds upon the SK Advantage Series and uses the same one-piece, conical seat design to provide the highest possible flow rate and bubble tight seal as well as easy assembly and maintenance.

Stainless Steel Spring-Loaded Piston Lift Check Valves CV9400 Series

- Soft Seat: Dyneon™M TFM1600 material enables bubble tight sealing performance under cryogenic conditions

- Seat Disc: Conical seat design provides higher Cv and a bubble tight seal

- Seat Assembly: One-piece assembly with no small pieces prevent possible dislodge of material during vibration that could damage downstream equipment or potentially cause an explosion

- Seat Holder: Lower position guiding ensures repeatability of tight reseal

- Spring: 316Ti material provides repeatable, lasting performance when exposed to cryogenic liquid

- Opening Pressure: 1.5 PSIG (0.1 BARG)

- Connection: SCH 10 Socket Weld & Butt Weld per ASTM A312 & ASME B16.25 standards

- Temperature rating: -320°F to +185°F (-196°C to +85° C)

- Pressure rating: Cold, non-shock, 720 PSIG (50 BARG) Class 300 (PN 50)

- Each valve is individually bagged and boxed to arrive in factory new condition until ready for installation

- Cleaned and packaged for oxygen service per CGA G-4.1