Regulator Lockup Troubleshooting

Field Topics are intended to provide useful information to the network of authorized LP-Gas and Anhydrous Ammonia distributors regarding the proper use of RegO® products.

Warning Bulletins covering many of the hazards involved are available from RegO for more detailed information. These bulletins can be found in our L-500, L-102 and NH3-102 catalogs. Neither the Field Topic or the Warning Bulletins are intended to conflict with federal, state, or local ordinances and/or regulations, which should be observed at all times. This information also is not intended to be a substitute for or to supplement any training in the safe handling and use of propane and related equipment, as required by any applicable law. By providing this material, ECI assumes no responsibility for providing any such training. Only individuals properly trained in the safe handling and use of propane and related equipment should be permitted to do so, and by providing this information, ECI does not assume responsibility for providing such training

For more information on LP Gas system requirements, refer to Liquefied Petroleum Gas Code (NFPA 58), National Fuel Gas Code (NFPA 54), National Propane Gas Association Safety Handbook, the RegO LP-Gas Serviceman’s Manual L-545, RegO catalogs L-500/L-102/NH3-102, ANSI K61.1 Safety Requirements for Storage and Handling of Anhydrous Ammonia, as well as any applicable local codes and ordinances.

Regulator Lockup Troubleshooting

When a properly installed RegO® regulator has a high lock-up, does not lock up, or is creeping, it is often caused by foreign material on the regulator seat disc. This Foreign could be copper flakes from your pigtail, pipe sealant, dirt and other forms of debris.

Foreign material can prevent the inlet nipple from properly seating on the seat disc. This material can come from system piping between the container shutoff valve and the regulator. Chips created during piping installation or dirty piping can create this hazard. Corrosion inside of copper pigtails and piping can cause problems. This can occur particularly when LP-Gas contains high sulphur or excessive moisture. Other debris that can be commonly found are shavings from polyethylene tube chamfer operations and pipe sealant due to excessive application.

Make sure regulator inlet piping is clean at the time of installation. Periodic inspections should take place to ensure piping remains clean without corrosion. Never use old pigtails on new LP-Gas installations. Old pigtails can harden and crack if they have been bent and twisted several times. When performing a leak check it is recommended to use a Presto-Tap® device to prevent movement of system piping.

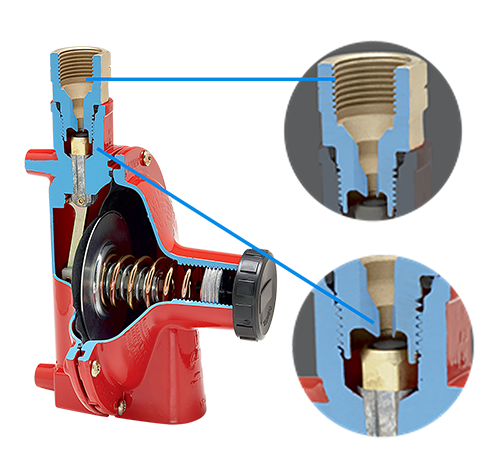

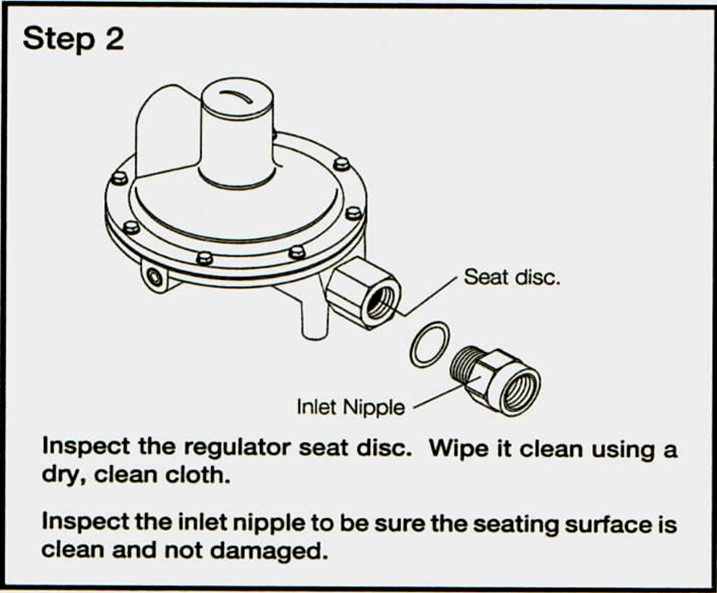

Inlet Nipple

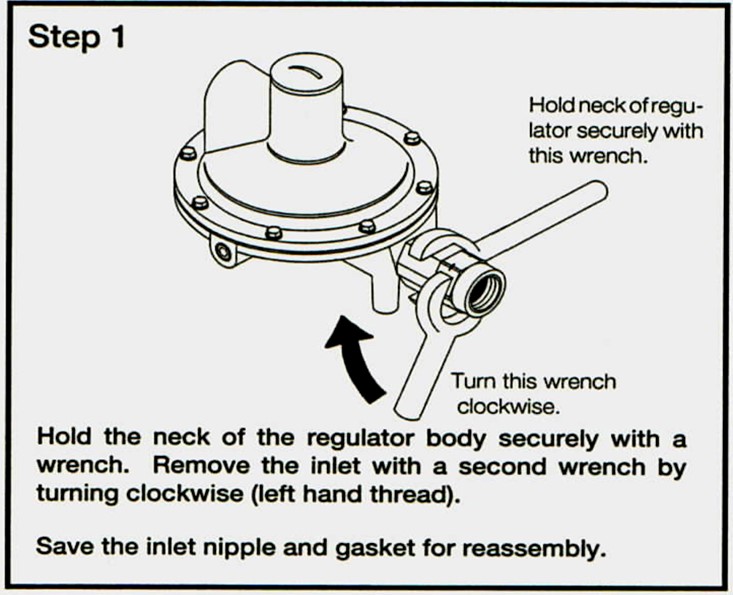

The Inlet Nipple is precision machined to prevent scoring of the seat disc. It can be removed to access the seating surface of the inlet nipple and seat disc.

Seat Disc

The resilient construction of the seat disc provides positive closure at lock-up pressure. It can easily be cleaned or replaced.

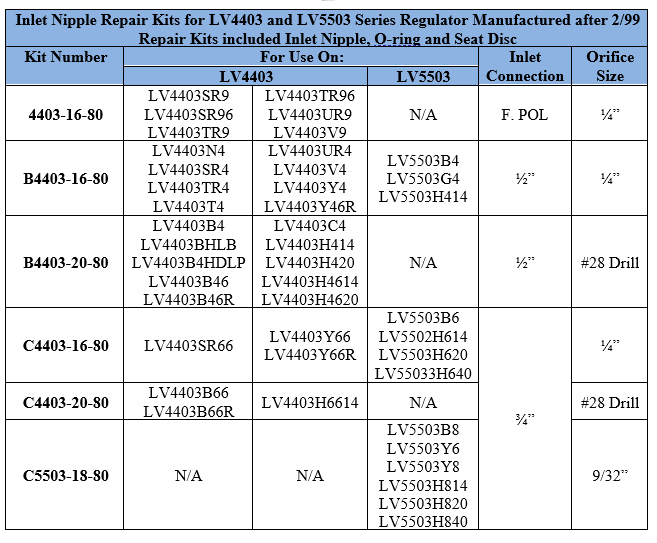

When a properly installed RegO LV4403 & LV5503 series regulator does not lock up or is creeping, what should you do?

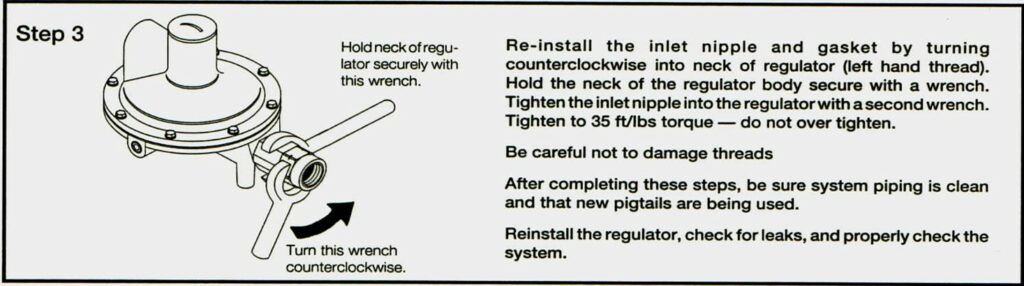

Simply remove the inlet nipple and wipe the seat disc off with a clean dry cloth. Inspect the inlet nipple and clean with a clean dry cloth if debris is present. Reinstall the inlet nipple and check for leaks and lock up. Repair kits are available for damage seat discs and inlet nipples.

An obstructed vent may prevent the pressure relief valve from operating properly.

Regulators should be installed with the vent facing down or protected so their operation will not be affected by the elements. In cases where the regulator vent is equipped with a discharge tube, the outlet of this tube must be facing down. The vents and/or discharge tubes must be protected from the elements and must be equipped with a screen to prevent insects from obstructing the opening.

Action Required:

Regulators should be properly installed and regularly inspected when tanks or cylinders are filled. If vents are clogged or the screen is missing, they must be cleaned or replaced. If the vent screen is missing and there is evidence of foreign material around the vent, the regulator should be replaced.

Other Causes of High-Pressure Gas in a System

Regulator vents that are clogged or obstructed. Vents must be kept clear and fully open at all times. Many regulators are equipped with a pressure relief valve which discharges to atmosphere through the vent. Ice, snow drifts, dirt, insects, paint, or other foreign material can clog the vents.

Wrong regulator installed for the application: The proper regulator must be used for each system.

For example, installation of high-pressure regulators not designed to reduce gas pressure to an appliance requirement of 11” w.c. will cause a hazard. Installing a regulator undersized for the load can cause improper combustion at the appliance burner with a potential for carbon monoxide poisoning.

Action Required: Make sure the regulator is correct for each application and test the system with a pressure gauge or a manometer.

Liquid propane in the regulator:

This can occur on recreational vehicles, unless the regulator is installed substantially higher than the container shut-off valve. Here, sloshing propane could get into the regulator with the resulting high pressure downstream of the regulator. It could also occur on stationary installations if the regulator is installed below the shut-off valve and the container is over-filled.

Action Required: Be careful of regulator installation and never overfill any LP-Gas container.

Failure to external mechanical parts due to corrosion:

Adjusting springs and relief valve springs can rapidly corrode if exposed to salt air or industrial pollution. Even moisture condensation on these springs can cause them to rust and fail.

Failure of these springs will result in failure of the regulator to control the pressure.

With the vent of a regulator facing down, corrosion products from the springs could clog the regulator vent screen blocking the vent.

Action Required: Regulator inspection for corrosion should be made according to the guidelines listed below:

- For underground installations subject to submersion, the regulator should be inspected every time the container is filled.

- For known corrosive atmospheres of salt air or chemical pollution, the regulator should be inspected at least once a year.

- For other applications, the regulator should be inspected every 3 years. If any corrosion is evident, replace the regulator.

- Any regulator that has been subjected to water should be replaced

It is essential that the regulator bonnet cap be tightly in place at all times to prevent the entrance of water, insects, dirt, etc. Foreign material can cause the regulator to function improperly with potentially hazardous results.

Field Topic Conductor :

Cody Reeves – LPG Tech. Services Manager

10+ years as a Propane Service Technician including installation and service of gas equipment.

State of CT Licensed Gas & Oil contractor.

Graduated from a Technical high school majoring in HVAC