A7796

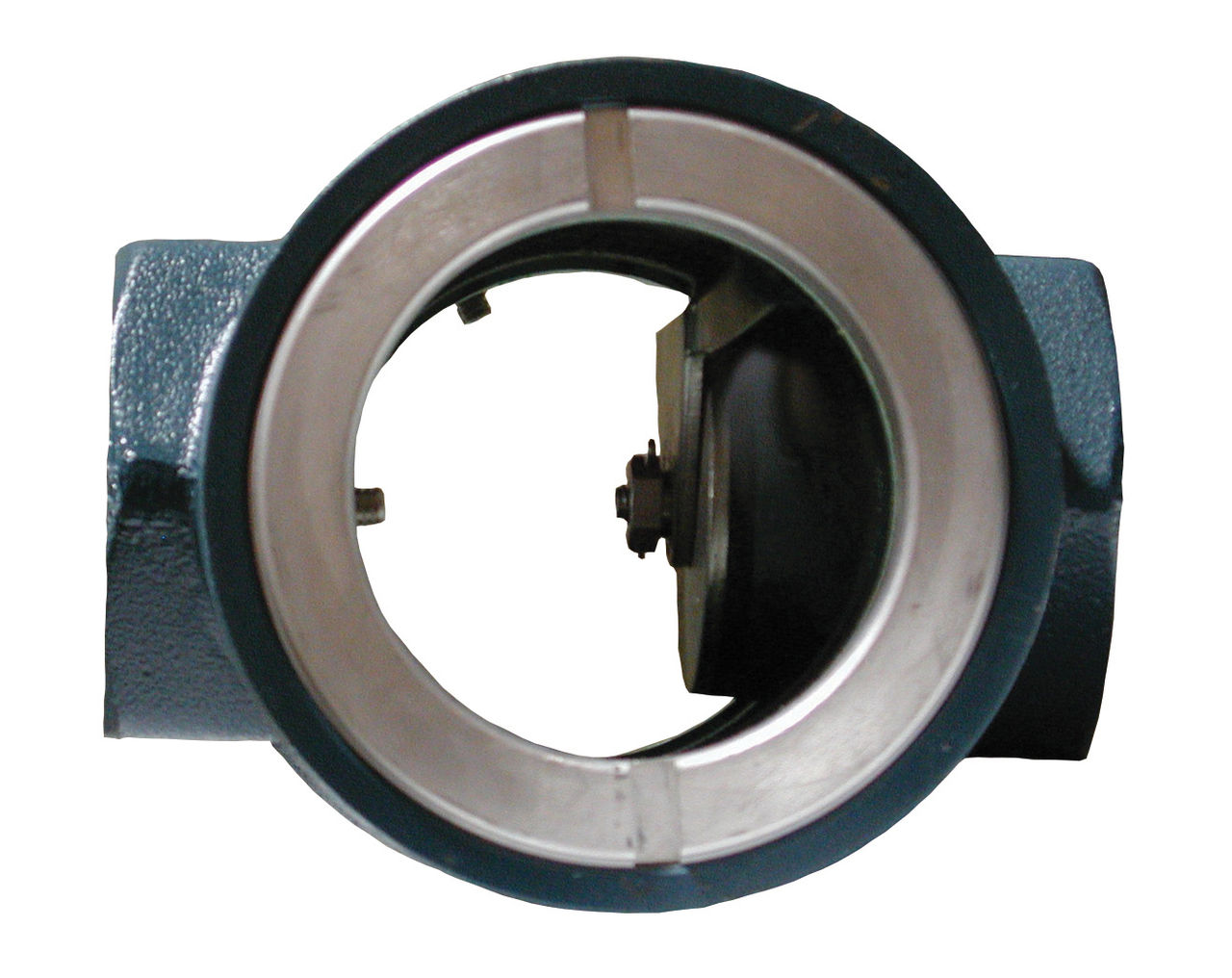

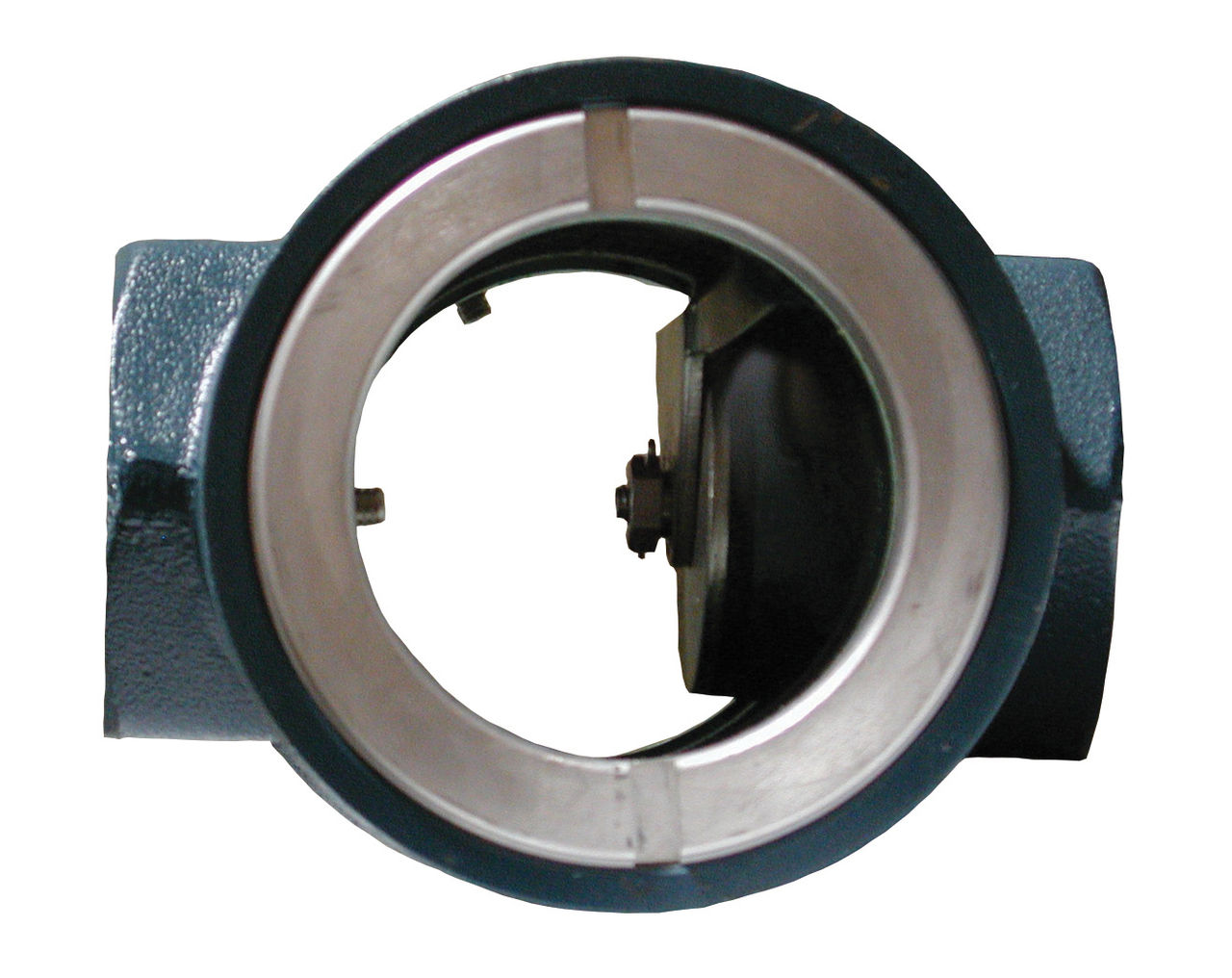

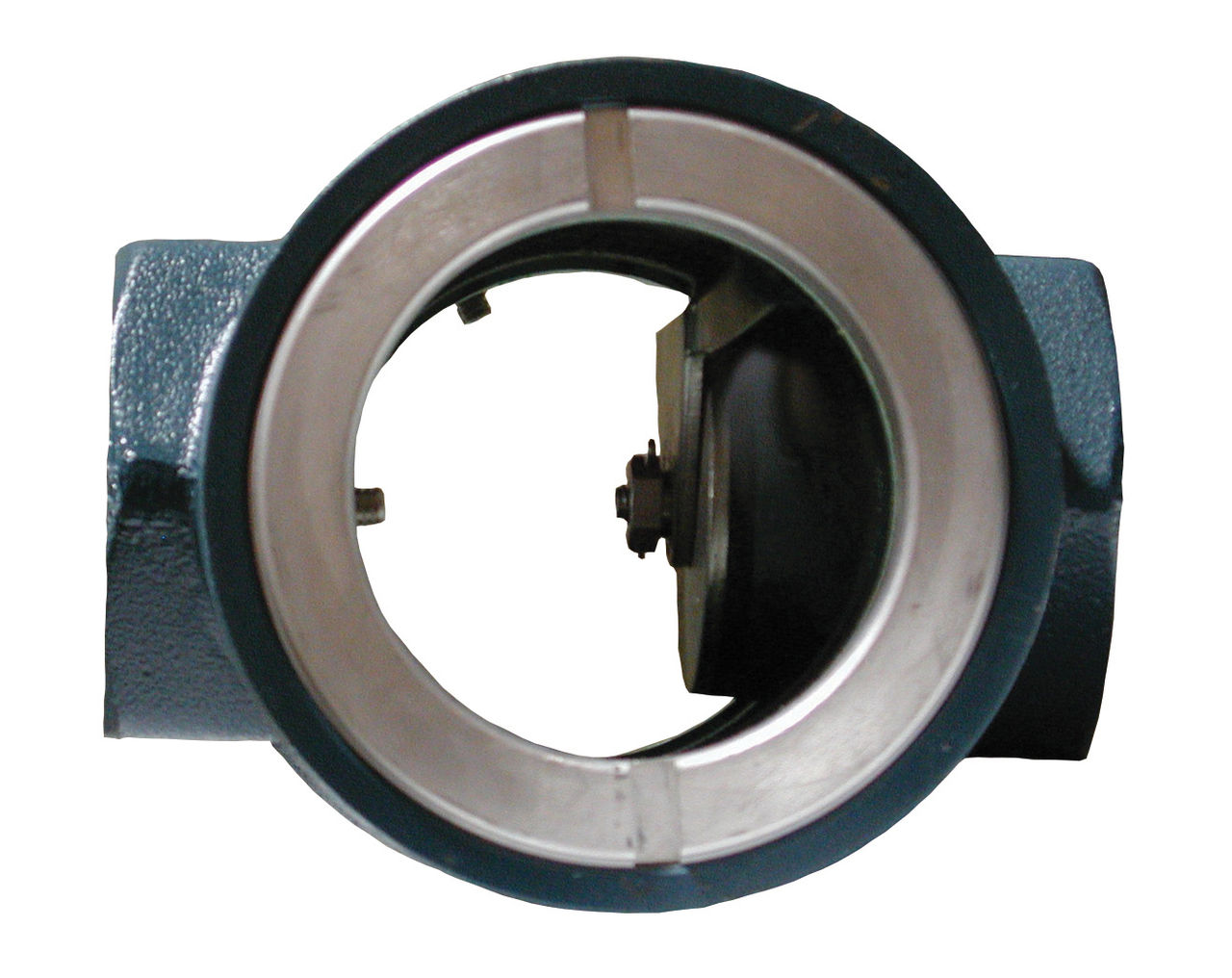

Designed to promote maximum pump efficiency, these indicators enable bulk plant operators to visually inspect liquid flow conditions. With glass on both sides of the indicator, flow can be observed from either side, even under some poor light conditions. The integral swing check also serves as a back-check valve to prevent reverse flow and product loss if the hose fails in a loading operation. By installing an indicator on the upstream side of the plant pump, suction conditions can be observed and the pump speed adjusted to obtain the maximum possible flow rate without cavitation. Additionally, if an indicator is installed in the piping at the loading rack, just ahead of the loading hose, the operator can maintain a constant check on pump conditions. Both installations are designed to allow for observation to provide maximum pump efficiency and ensure safe plant pump operation. In compressor operations a sight flow indicator installed in the liquid line will give a visual indication when the tank car or transport is emptied. Compressor operation can then be immediately reversed to start recovery of the vapor.

Markets

Agriculture Energy & Power

Applications

Bulk Storage

Loading

Need help? Contact support.

Customer Support

Reach Out to Our Customer Support Team for Prompt Assistance and Answers to Any Questions or Concerns You May Have

Technical Support

Contact Us for Technical Support on Your Projects and Resolving Any Technical Issues You Encounter

Contact a Distributor

Locate a Nearby Distributor for Replacement Parts

Product Enquiry

Product Information request form to find the right solution

Need help? Contact support.

Customer Support

Reach Out to Our Customer Support Team for Prompt Assistance and Answers to Any Questions or Concerns You May Have

Technical Support

Contact Us for Technical Support on Your Projects and Resolving Any Technical Issues You Encounter