1 ¾” ACME Double-Check Filler Valves

Field Topics are intended to provide useful information to the network of authorized LP-Gas and Anhydrous Ammonia distributors regarding the proper use of RegO® products. Warning Bulletins covering many of the hazards involved are available from RegO for more detailed information. These bulletins can be found in our L-500, and NH3-102 catalogs. Neither the Field Topic or the Warning Bulletins are intended to conflict with federal, state, or local ordinances and/or regulations, which should be observed at all times. This information also is not intended to be a substitute for or to supplement any training in the safe handling and use of propane and related equipment, as required by any applicable law. By providing this material, ECI assumes no responsibility for providing any such training. Only individuals properly trained in the safe handling and use of propane and related equipment should be permitted to do so, and by providing this information, ECI does not assume responsibility for providing such training.

For more information on LP Gas system requirements, refer to Liquefied Petroleum Gas Code (NFPA 58), National Fuel Gas Code (NFPA 54), National Propane Gas Association Safety Handbook, the RegO LP-Gas Serviceman’s Manual L-545, RegO catalogs L-500/NH3-102, ANSI K61.1 Safety Requirements for Storage and Handling of Anhydrous Ammonia, as well as any applicable local codes and ordinances.

1 ¾” ACME Double-Check Filler Valves

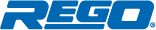

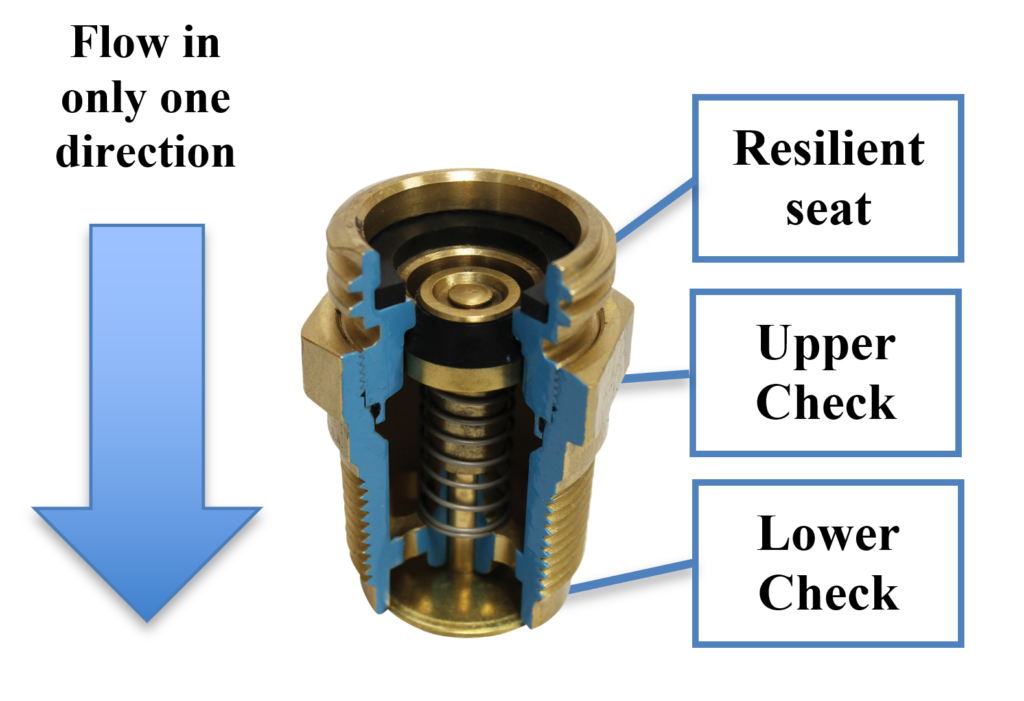

RegO Double-Check Filler Valves incorporate a resilient upper check valve–normally designated as a filler valve–and a lower check valve, commonly called a back pressure check valve.

Flow of liquid into the storage container opens both check valves. When flow stops, they both are designed to close automatically to permit the operator to disconnect the hose coupling. The automatic closing action also helps prevent the discharge of container contents in the event of hose failure.

The lower back pressure check provides extra protection by restricting the discharge if the upper check fails to function properly due to accidents or other causes. The RegO Filler valve design allows for emergency inspection, repair, or replacement of the upper fill assembly without removing product from the container. When the upper filler valve body is removed, the lower back check valve provides a seal, permitting only minimal leakage, allowing a new upper filler valve body to be installed.

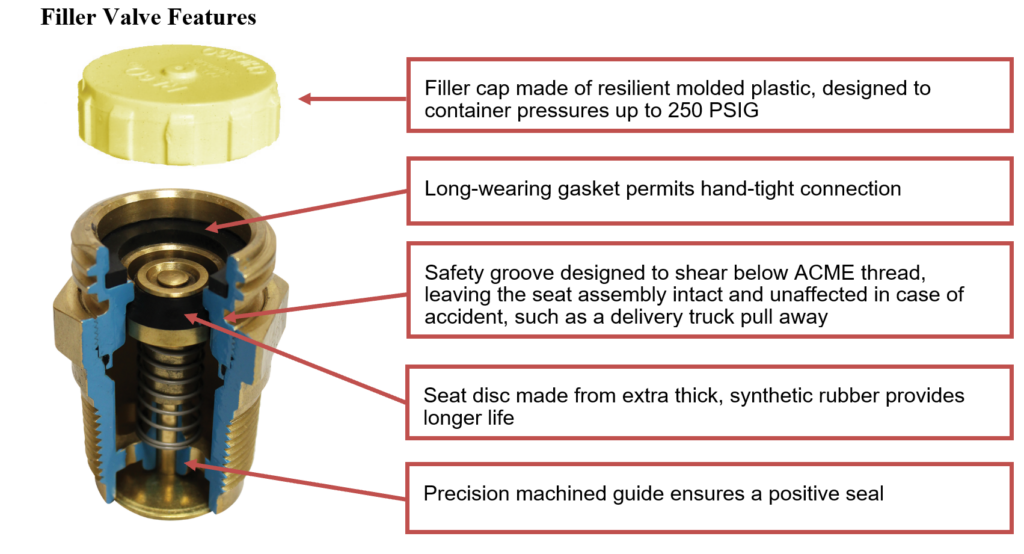

Low Emission Filler Valves

Low Emission Filler Valves discharge less than 4 cubic centimeters when used in conjunction with a RegO Low emission hose end valve. This design meets the requirements of NPFA 58 for a low emission transfer site, other requirements must be met to distance requirements. Additionally, these products, when used in conjunction, meet the requirements for a low emission connection of California CARB Rule 1177.

6579 Swing Check Low Emission Filler Valves

Low Emission Filler Valves discharge less than 4 cubic centimeters when used in conjunction with a RegO Low emission hose end valve. This design meets the requirements of NPFA 58 for a low emission transfer site, other requirements must be met to distance requirements. Additionally, these products, when used in conjunction, meet the requirements for a low emission connection of California CARB Rule 1177.

E7579 Extended Low Emission Filler Valves

The E7579 is designed with an extended upper body portion to add some additional height on the filler valve. The additional height of the upper body eliminates the need for a filler extension and reduces the chance of exposure to dirt, debris, etc. that typically occur in above-underground tank applications. In addition, the valve also provides a low emission connection. The EG167 is available to extend the gauge device: providing a clearer visibility of the container level percentage.

Overfill Protection Device Filler Valves

Overfill Protection Device (OPD) Filler Valves are designed to stop the flow of product into the container when the liquid level reaches approximately 80% of its capacity. The integral float will stop the product flow when the liquid level meets the predetermined level. To select the correct OPD filler valve, the dimension from the top of the container coupling and 80% level must be determined. This can commonly be referenced from the dip tube length on the container’s data plate.

Integral Manual Shut-off Filler Valves

The 7501L/7502L provides a positive manual shutoff between the upper and lower check assembly. When filling a container from a delivery truck, this valve will allow flow into the container through the upper and lower check when the manual lever is in the open position. When flow stops, both the upper and lower checks will close; the lever is then turned to the closed position, and the hose-end valve can then be removed from the filler valve. This filler valve can be commonly found on containers at cell tower locations meeting requirements of NFPA 58.

7579P Pipeaway Filler Valve

The 7579P is designed to provide fast filling of ASME domestic containers. The valve incorporates a ¾” F. NPT connection for a diptube that extends down to the bottom of the container. To allow the removal of liquid propane with the use of a RegO unloading adapter. Note containers manufactured before December 1, 1963 had no provision for a liquid withdrawal valve or Chek-Lok® device. Chek-Lok valves are commonly found on new containers.

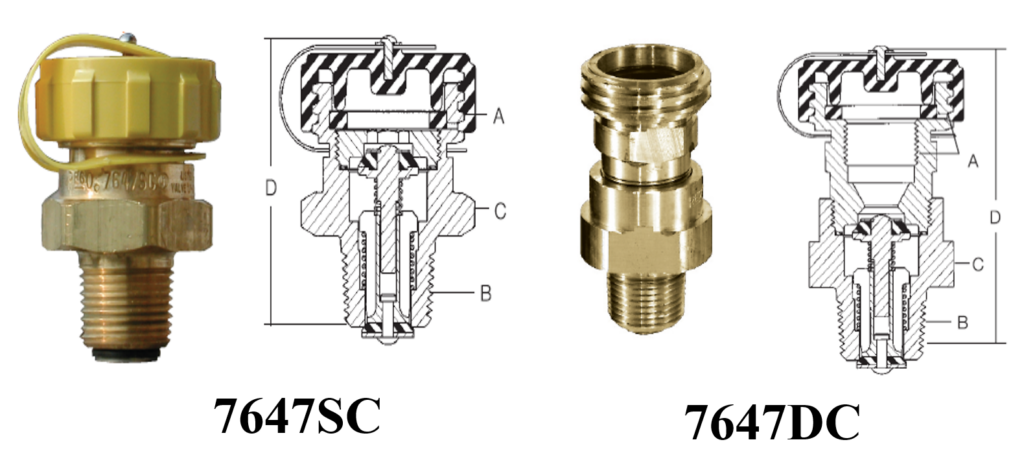

7647SC & 7647DC Double Check Filler Valves

The 7647SC & 7647DC are designed to provide fast filling of forklift, motor fuel, and recreational vehicle tanks. The lower check includes a soft seat to provide a gas tight seal with zero leakage. The lower seat allows repairability of the upper check without discharge of propane during the repair process. The 7647DC incorporates a F. POL connection for filling thru a M. POL hose end adapter.

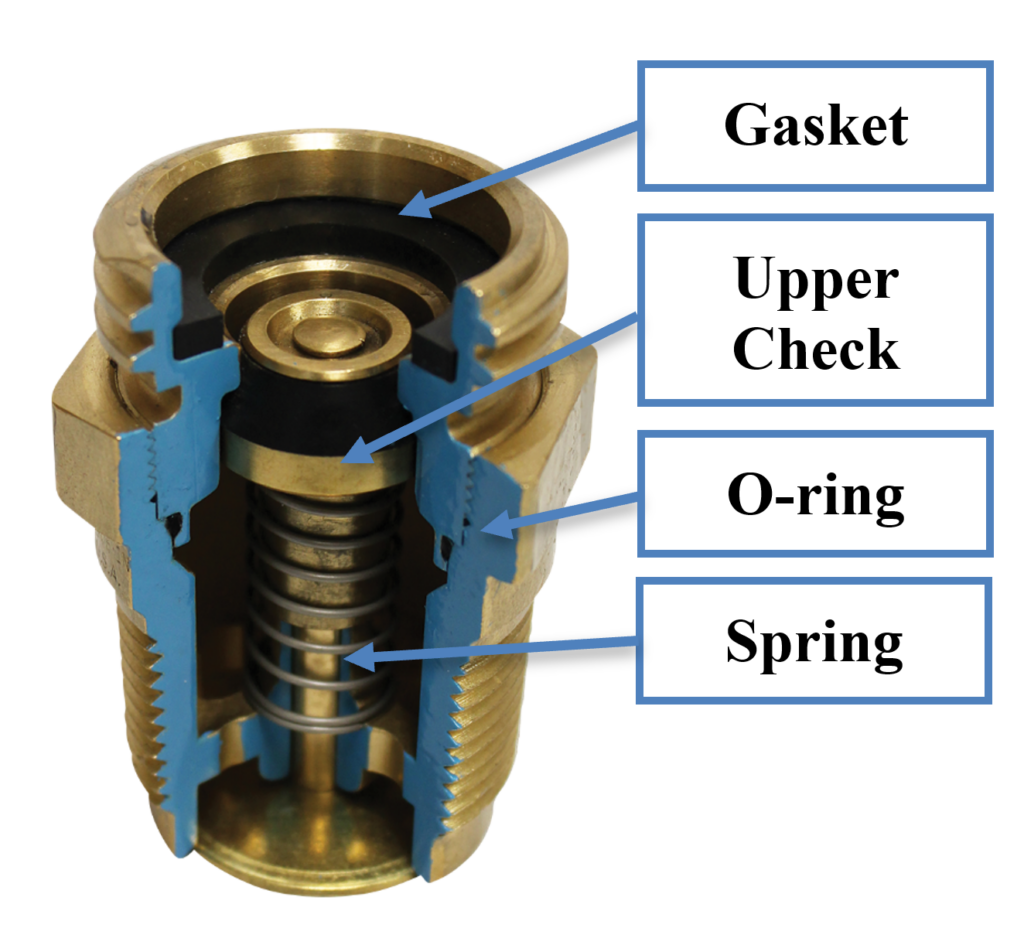

Repairability of Filler Valves

The construction of RegO filler valves allow for emergency inspection, repair, or replacement of the upper fill assembly without removing product from the container. When the upper filler valve body is removed, the lower back check valve provides a seal, permitting only minimal leakage, allowing a new upper filler valve body to be installed.

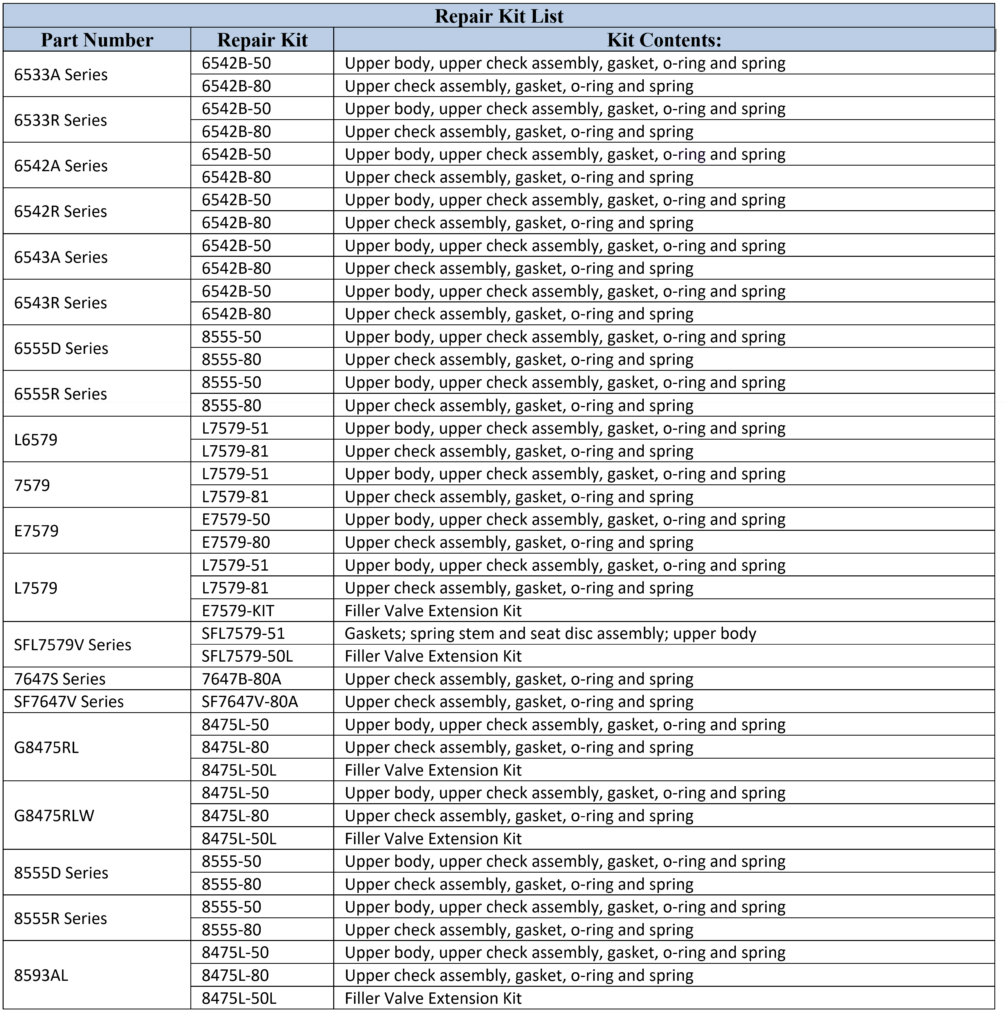

Repairability of Filler ValvEach filler repair kits comes with detailed instructions to complete the repair allowing for the replacement of the upper check, gasket, O-ring, spring, and upper body. Repair kits ending in -50 will include upper check, gasket, O-ring, spring and upper body. Repair kits ending in -80 will include upper check, gasket, O-ring, and spring. Note: Be sure all instructions (included with the kits) are read and understood before any installation, operation, and maintenance.

Should you have any questions or concern, please contact Cody Reeves.

Field Topic Conductor :

Cody Reeves – LPG Tech. Services Manager

10+ years as a Propane Service Technician including installation and service of gas equipment.

State of CT Licensed Gas & Oil contractor.

Graduated from a Technical high school majoring in HVAC