Dielectric Fitting Requirements

Field Topics are intended to provide useful information to the network of authorized LP-Gas and Anhydrous Ammonia distributors regarding the proper use of RegO® products. Warning Bulletins covering many of the hazards involved are available from RegO for more detailed information. These bulletins can be found in our L-500, and NH3-102 catalogs. Neither the Field Topic or the Warning Bulletins are intended to conflict with federal, state, or local ordinances and/or regulations, which should be observed at all times. This information also is not intended to be a substitute for or to supplement any training in the safe handling and use of propane and related equipment, as required by any applicable law. By providing this material, ECI assumes no responsibility for providing any such training. Only individuals properly trained in the safe handling and use of propane and related equipment should be permitted to do so, and by providing this information, ECI does not assume responsibility for providing such training.

For more information on LP Gas system requirements, refer to Liquefied Petroleum Gas Code (NFPA 58), National Fuel Gas Code (NFPA 54), National Propane Gas Association Safety Handbook, the RegO LP-Gas Serviceman’s Manual L-545, RegO catalogs L-500/NH3-102, ANSI K61.1 Safety Requirements for Storage and Handling of Anhydrous Ammonia, as well as any applicable local codes and ordinances.

Dielectric fittings are designed to isolate potential electrical current from metallic piping and tubing. This helps in preserving the piping and preventing the unintentional production of electricity, which could result in damage caused by corrosive actions.

When is it required to install a dielectric fitting?

Dielectric fittings are required per NPFA 58 on underground metallic piping, tubing, or both that convey LP-Gas from a container. The installation of the dielectric fittings is required to be in the aboveground portion of the fixed piping system that enters a building.

RegO Dielectric second stage regulators are engineered to isolate potential electrical current from metallic piping before entering a building. The use of a separate dielectric union is not necessary because the regulator contains a dielectric union as part of the inlet assembly. Available in both SAE Flare and F.NPT inlet connection.

Dielectric Fittings on Underground Containers

It is recommended to provide electrical isolation of an underground container from metallic piping. The cathodic system that protects an underground container that is not electrically isolated from the attached metallic piping system will be required to be properly sized to protect the container and connected piping system. If the piping is of a different material from the container, such as copper, it is possible that corrosion may occur even though a sacrificial anode is connected to the container. In general, copper piping does not require cathodic protection.

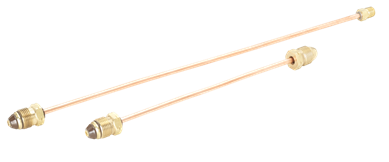

RegO D912 & D913 Series Pigtails are designed specifically for use on Underground Containers where dielectric isolation is necessary to protect the container.

Dielectric Pigtails are intended to be installed by using the same amount of installation torque as any other pigtail on the POL container service connection. When installing the D912 or D913, care must be taken to prevent the tubing and regulator from touching the container shell or the protective dome and cover. Contact between the unprotected tubing or regulator and the container or dome could create an electrical connection reducing or eliminating the dielectric isolation protection. The use of non-conductive pipe insulation over the pigtail tubing and metallic tubing could be used for ensuring isolation from the container.

Should you have any questions or concern, please contact Paul Courson

Paul Courson

LPG & NH3 Technical Director

O: +1 336.446.7292

Paul.Courson@regoproducts.com